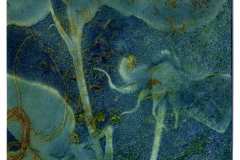

The images on this page were made by layering multiple processes. For instance, photopolymer prints made with a printing press were coated with cyanotype chemicals and then exposed to ultraviolet light. The resulting colors and textures are rich and pleasing to the eye.

About these alternative processes:

When I first started working with the cyanotype process I thought it a rough and unstable process. Paper is made light-sensitive by brushing a solution of iron compounds, ferric ammonium citrate and potassium ferricyanide, onto the paper’s surface in subdued light and letting it dry in the dark. The solution is sensitive to the UV spectrum of light, so exposure is made in direct sunlight or special UV lamps. Development is done in water, no fixing needed.The results were not predictable and, at its best, interesting but crude. However, after working with the process for a while, I started to get some more positive results. Variations in shades of blue became possible and image detail more visible. I feel that I have only just begun to touch the surface of the many ways to explore the cyanotype process.